Table of Contents

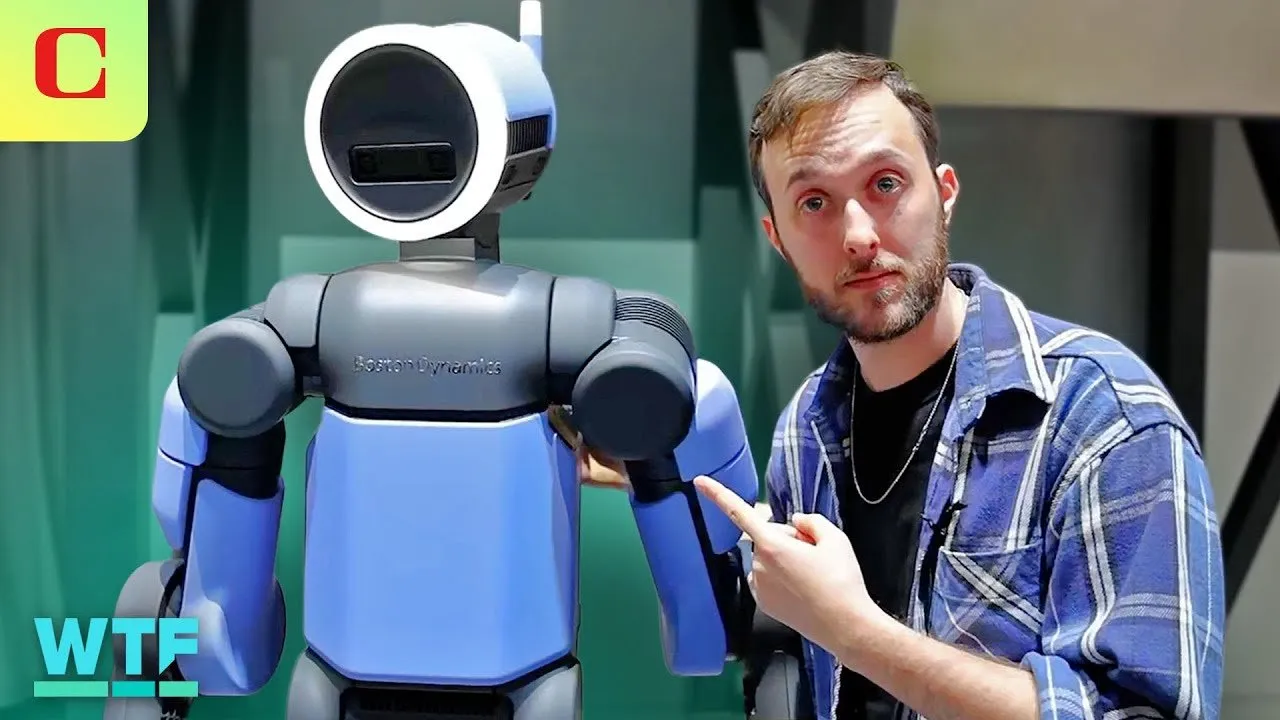

Boston Dynamics has officially debuted the production model of its iconic Atlas humanoid robot at CES, marking a pivotal transition from research and development to commercial viability. Showcased within a simulated factory environment under the stewardship of parent company Hyundai, the new electric Atlas demonstrated a blend of autonomous operation and real-time human-assisted learning designed for industrial application.

Key Takeaways

- Commercial Timeline: Internal deployment is scheduled for 2026, with mass production targeted for 2030.

- Industrial Specs: The robot stands 6'2", lifts up to 110 lbs, and operates on a 4-hour hot-swappable battery system.

- Hybrid Learning: Atlas utilizes a "human-in-the-loop" system where operators correct mistakes to refine autonomous behavior.

- Safety Design: Engineers have removed pinch points and implemented a "controlled sit-down" protocol for emergency stops.

From Lab Experiment to Factory Floor

While previous iterations of Atlas were famous for parkour and dance videos, the unit displayed at CES focuses strictly on utility. The demonstration highlighted the robot's ability to move automotive parts in a factory-like setting. While early walking demonstrations utilized remote control to test natural gait patterns, the current production focus is on autonomy.

The system employs a learning model where the robot attempts tasks autonomously. If Atlas encounters an error or is about to make a mistake, a teleoperator intervenes. This human input corrects the action, effectively teaching the robot how to resolve the issue independently in the future. This real-time learning loop is essential for the variable conditions of active manufacturing floors.

Technical Specifications and Performance

The production Atlas is significantly more imposing than its predecessors. Standing 6 feet 2 inches tall, the robot is designed to manipulate objects up to 7.5 feet away. It possesses a lift capacity of 110 lbs, making it capable of handling heavy industrial components.

To ensure continuous operation, Boston Dynamics has equipped the unit with two batteries located on its back. These allow for a four-hour runtime and are hot-swappable, meaning the robot does not need to power down for a battery change. According to company representatives, future capabilities will allow Atlas to change its own battery, further reducing the need for human maintenance.

Durability and environmental resistance are also key upgrades. The robot features active self-cooling vents allowing it to operate in temperatures up to 104°F. Mechanically, the design has been simplified to use only two types of actuators—large and small—streamlining supply chains and repairs. Notably, the new joint architecture allows for 360-degree swiveling, offering a range of motion that exceeds human limitations.

Design Philosophy and Safety Protocols

Boston Dynamics has made deliberate aesthetic choices to distinguish the machine from its human coworkers. The new model features a faceplate that avoids uncanny valley characteristics, a decision driven by the desire to manage expectations regarding the robot's intelligence.

"It's not a human. And I think it projects the wrong first impression about a robot to have it pretend to be something that it's not. And particularly, over the early days, maybe the next 5 years to a decade, the robots are not going to be as smart and as capable as people."

Safety remains a paramount concern for heavy industrial machinery working alongside humans. The engineering team has designed out most physical pinch points to prevent injuries during handling or accidental falls. Furthermore, the emergency stop (E-stop) protocol has been reimagined. Rather than cutting power immediately—which would cause the heavy unit to collapse dangerously—triggering the E-stop forces Atlas into a "controlled sit down," returning it to a neutral, safe position.

Commercialization Roadmap

Boston Dynamics has outlined a clear, phased approach to bringing Atlas to market. For 2026, deployment will be restricted to "within the family," specifically for use by Hyundai, DeepMind, and Boston Dynamics. By 2027, the company plans to expand pilot programs to related industries.

The company aims to scale manufacturing capabilities in 2028, setting the stage for full mass production by 2030. While pricing details remain undisclosed, the strategic rollout suggests a focus on high-value industrial sectors where productivity gains can justify significant capital investment.